Slag | Edw. C. Levy Co.

Click the images below to see Product Guides. 21AA Blast Furnace Slag. 22X Steel Furnace Slag

WhatsApp)

WhatsApp)

Click the images below to see Product Guides. 21AA Blast Furnace Slag. 22X Steel Furnace Slag

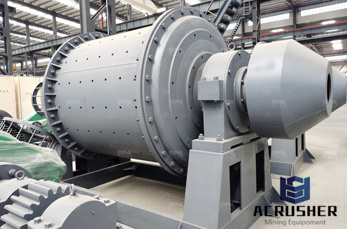

40tph Slag Vertical Mill Grinding Plant picture from Jiangsu Pengfei Group Co., Ltd. view photo of Cement Line, New Type Dry Cement Line, Vertical .

The matte and slag tapping practices are also similar. The Noranda process, as originally designed, allowed the continuous production of blister copper in a single vessel by effectively combining roasting, smelting, and converting into 1 operation. Metallurgical problems, however, led to the operation of these reactors for the production of copper

Slag from steel mills in ferrous smelting, on the other hand, is designed to minimize iron loss and so mainly contains oxides of calcium, silicon, magnesium, and aluminium. Any sandy component or quartz component of the original ore automatically carries through the smelting process as silicon dioxide.

Slag glass, also known as marble glass or malachite glass, is a type of opaque, streaked pressed of slag glass originated in late19thcentury England, where glass manufacturers are thought to have added slag from ironsmelting works to molten glass to create a range of effects—from tortoiseshell to marbling.

Steel slag can be processed into a coarse or fine aggregate material for use in dense and opengraded hot mix asphalt concrete pavements, (1,2,3) and in cold mix or surface treatment applications. (4) Proper processing of steel slag and special qualitycontrol procedures are extremely important in selecting steel slag for use in asphalt paving ...

Oct 26, 2019· Gold smelting is a metallurgical process used to separate metal from ore, rocks that contain gold. The ore is ground and treated with chemicals to remove some impurities before being heated at high temperatures with a flux that triggers a chemical reaction, causing the metal to precipitate out of the mixture.

Sep 01, 2017· This is most dangerous work with steel plant and production [slag explosion, kress slag pot carrier] If you like this videos please click Like, Comment and . Thanks for watching!! For more ...

User Guidelines for Waste and Byproduct Materials in Pavement Construction ; Publication Number: FHWARD97148 ... Grinding slag for cement replacement requires only about 25 percent of the energy needed to manufacture Portland cement. ... typically using the same or similar plant and equipment as for Portland cement production.

Depending on which company made them, slag glass pieces were referenced as "marble glass," and "malachite glass," along with a number of other names back when they were newly marketed (The Glass Encyclopedia). Slag glass was often used in lampshade production as well as for crafting many different types of decorative objects.

The Slug Catcher helps protect your valuable production equipment from abrupt large bursts of liquids entering your gas stream. It is typically used downstream of pipeline and pigging operations where large volumes of liquid can collect in the pipeline and are pushed through in a short time.

Non ferrous slags make up only 12% of the total annual production Described below are the main types and uses of slag commercially available in Ferrous Slag products. Iron Blast Furnace Slag (BFS) This is the coproduct from the reduction of iron ores to produce molten iron and molten slag. 1.

Zhengzhou Leizhan Technology Paper making machinery Co.,Ltd is a professional manufacturer of pulp and papermaking equipments, which engaged in research and development, manufacture and sale, now has successfully developed the marketable high consitency pressure screen, inflow pressure screen and D type Hydrapulper, and become the leader manufaturer in this area for the domestic ...

(2) The production of expanded blast furnace slag is no longer favored and is being replaced by the pelletizing procedure. ACBFS has been used as an aggregate in Portland cement concrete, asphalt concrete, concrete, asphalt and road bases. Pelletized blast furnace slag has been used as lightweight aggregate and for cement manufacture.

759 blast furnace slag products are offered for sale by suppliers on, of which slag accounts for 17%, refractory accounts for 15%, and mine mill accounts for 8%. A wide variety of blast furnace slag options are available to you, There are 682 suppliers who sells blast furnace slag on, mainly located in Asia.

ductile iron production has experienced continued growth, the quality of metallic scrap and other ironunit feed stocks has steadily deteriorated. The result: slag related melting problems have become widespread issues in recent years. Yet, a search of the foundry technical literature from the past 30

Discover Hollywood''s source for motion picture and digital video equipment including grip and lighting equipment to expendables. Filmtools: Hollywood''s Source for Motion Picture and Digital Video Equipment and Supplies Filmtools

Kress Corporation is the world''s leading manufacturer of slag pot carriers, with hundreds of units in operation throughout the world in the steel, nonferrous, and ferroalloy industries

Jun 27, 2019· 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations ...25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag .

Although slag production weight is variable, a typical operation can generate 10 kilos of slag per 1000 oz of gold. The precipitate obtained in the MerrillCrowe process is very sensitive during the smelting process due to the process employ diatomaceous earth as a filtration medium.

EXCEPTIONAL CASTING CAPABILITIES BROUGHT TO LIGHT. We are a leading manufacturer of high performance steel millrelated castings, including the world''s finest slag pots, coiler drums for steckel mill applications, mechanical mill parts and metalworking press castings.

Blast furnace slag is allowed to slowly cool by ambient air, is processed through a screening and crushing plant and is processed into many sizes for use primarily as a construction aggregate. Common uses are as aggregates in readymix concrete, precast concrete, hot mix asphalt aggregate, septic drain fields and pipe backfill.

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine granulated blast furnace is highly cementitious and high in CSH (calcium silicate hydrates) which is a strength enhancing ...

Slag wool is made from blast furnace slag, a waste byproduct of steel production. The industry estimates that over 90 percent of the slag used for insulation is purchased directly from steel manufacturers. The remaining 10 percent is mined from waste disposal sites and landfills.

WhatsApp)

WhatsApp)