Sinoma Technology Equipment Group CO.,LTD

Overland Curved belt Belt Conveyer. Rotary Kiln. No. Users: Model: Name: Plant Capability: Qty.(set) 1: Shanxi Shehui cement Co.,Ltd

WhatsApp)

WhatsApp)

Overland Curved belt Belt Conveyer. Rotary Kiln. No. Users: Model: Name: Plant Capability: Qty.(set) 1: Shanxi Shehui cement Co.,Ltd

Sinoma Int., a Fullservice General Contractor with: A workforce of more than 10,000 employees; Global presence in around 70 countries and regions

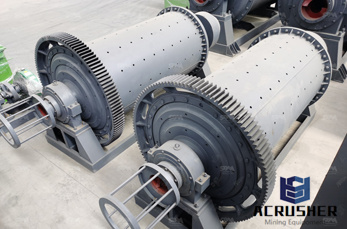

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

With independent research and design, SINOMALY is the leading manufacturer of mining equipment and crushing equipment. Our products have been exported to USA, Russia, Nigeria, Brail, Peru, etc.

ball mill> Sinoma Zhuzhou Cement Plant; Sinoma Zhuzhou Cement Plant. Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Sinoma Cement industry news from Global Cement The Loesche mill will grind cement raw material at a production rate of 420t/hr with a fineneness of ... Sinoma Group is constructing the /yr new cement .

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Cement mills and raw mills .

The Oman Project was formally put into production (added with 30% of ball load) on April 1st, subsequently the cement grinding mill ball load was gradually added up to 85% on 22nd April. Up to 24th April, 10,000t cement was produced with a peak feeding capacity of 210 t/h (approximately 90% of the rated output) for the Cement Mill System ...

complete set of cement production line provided by Jiangsu Pengfei Group | Equipments for compound fertilizer | industrial furnace |mining mill | slag mill | vertical roller mill| roller press| cement tube mill| ball mill| drying and middle discharging raw mill | grinding equipments | cement rotary kiln| red claynickel ore rotary kiln | lime rotary kiln| oxidation palletizing rotary kiln ...

Close Curcuit Cement Plant Sinoma China. Processing ability: –500 t/h Feeding size: ≤25 mm Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ...

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the ...

Ball Mills. AK Multimetals Pvt Ltd. Al Bijjar Trading (FZC). ... Cementrade is a supplier of grinding media, lining for cement, raw mills and heat resistant casting. Cemtec Cement and Mining Technology . ... dominion used ball mill . Remas. Saboo Technologies. Santasalo .

sinoma technology amp amp equipment group co. For more than 30 years Chinabased Sinoma Technology Equipment Group Co Ltd Sinomatec Roller Mill China Cement Ball Mill Crusher Mills Cone More stone crushing sinoma keslerconstruction s stone crusher ball mill bekas raw mill sinoma raw meal mill sinoma liyang heavy machinery co sinoma cement mill ø5000 serdindiaorgin

View Our Latest Projects. Have an idea, a dream? We can make it happen. CLICK HERE!

The capacity of the vertical mil will be 2500 kW, mill output 270t/h, fineness 80um and 15% residue on sieve. The signing of this contract marks SinomaTec''s exploration of new market in raw meal vertical mill (SHMG) and ball mill upgrading.

Liyang Sinoma Raw Material Vertical Mill. grinding machine sinoma vertical roller mill at Vertical roller mill is a kind of energy efficient grinding machines which is widely used in many fields such as producing raw and clinker material grinding slag ore industrial silicon calcium carbide residue coal gangue in the cement industry and desulphurization process in the industries of

Ball Mill. Ball mill machine is widely applied in the industries, such as cement, silicate product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc. It is mainly used to make dry or wet powder grinding of various ores and other grindable materials. Working Principle Of Ball Mill:

Over 26 years'' development, Sinoma Overseas have spread its business to Southeast, Middleeast, Africa and South America and other districts all over the world, have contracted projects including cement, glass, refractory, power facilities etc. under the EPC turnkey basis and provided production operation services for a large number of ...

Indonesia: ABB, a power and automation technology group, has won an order from Tianjin Cement Industry Design Research Institute Co. Ltd, a subsidiary of Sinoma Group, for a variablespeed drive solution for a dual pinion ball mill at the PT Semen Bosowa Maros cement plant in Indonesia.

Sinoma Cement Ball Mill Stone Crusher Usa Crushers Sale Usa Crushing Equipment ZENITHs stone crusher is designed to achieve larger productivity and higher crushing ratio From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers ZENITH can supply the right crushers ...

Close circuit ball mills with high efficiency separators are being preferred by Indian cement producers, in cases where the capacity requirements are low. Upgradation of ball mill systems is driven mainly by the resulting energy efficiency visavis the payback periods.´ Sa is on the same page.

Article: Innovations for Optimization at Liulihe Cement WL Gore, chinese cement milling producer,to previous nonmembrane filters, which they have been using The result of the optimisation has been a substantial increase in production through the mill Background China is the world''s largest producer of cement The Chinese supplies drive system for world''s most powerful ...

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

WhatsApp)

WhatsApp)