Roller Compactor: Basic Principles and Applications in ...

Apr 16, 2017· Roller Compactor: Basic Principles and Applications in Pharmaceutical Industry Published on April 16, 2017 April 16, 2017 • 34 Likes • 10 Comments

WhatsApp)

WhatsApp)

Apr 16, 2017· Roller Compactor: Basic Principles and Applications in Pharmaceutical Industry Published on April 16, 2017 April 16, 2017 • 34 Likes • 10 Comments

Jul 20, 2013· The mixing is often done on a tworoll mill (open mill). A mill consists of two horizontally placed hollow metal cylinders (rolls) rotating towards each other. The distance/gap between the mill rolls (nip) can be varied, typically between 2 to 20 mm. Rolls Friction Ratio The speeds of the two rolls are often different, the.

Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product.

The American Radio Relay League (ARRL) is the national association for amateur radio, connecting hams around the with news, information and resources.

We are committed to serving our students by fostering an environment which positively impacts their character development and empowers them to realize their fullest academic potential, thus allowing them to become comprehensive, creative and critical thinkers in .

Qst In Roll Mill Principlesqt A Block Machine Price From Small Business Idea. Solutions. pigment grinding pigment edgeead. This new development combines easy handling and revolutionary machine technology with ergonomic design Pigment Grinding Machine, Pigment Pigment Grinding Mill, Pigment Grinding qst in roll mill principlesqt a block ...

e 1 Rolling processes 51 introduction: Rolling is the process of reducing the thickness or changing the cross section of a long workpiece by compressive forces applied through a set .

The Principles and Building of SSB Gear Part 4 QST December 1985, pp. 3740 Let''s discuss VFOs and examine a practical circuit for use with our SSB transmitter. Emphasis is on stability and purity of the VFO signal. The Principles and Building of SSB Gear Part 5 QST January 1986, pp. 2932 Man does not live by milliwatts alone!

Apr 01, 2018· On this channel you can get education and knowledge for general issues and topics

QST QST is the monthly membership journal of ARRL. Each issue is your source for equipment reviews, technical tips, projects, and news. Join the ARRL today to start receiving your monthly issue of QST in print AND digitally.

The principle of mill operation is the impingement of the solids between pieces of media. The majority of media motion and milling occurs on the surface of the bed of media where the media is cascading. If there are too few solids, then media will strike media with little milling effect but with accelerated wear of the media and mill shell. ...

qst in roll mill principles qst in roll mill principles principle of 3 roll milling grinding mill equipment Roll Mill Working Principle crushervanguardiatravelmx Three roll mill ore crusher price A three roll mill or triple roll mill is a machine that uses shear force Ink Three Roll Mill.

Dec 12, 2014· An animation to demonstrate the process of an Automatic Roller Mill and the break down of particles to the correct precise size for animals to digest food in a safer way.

Subject: Press and Dryer Roll SurfacesQuarterly Report #I Valri, f=CE!WEaz; JU1 2 9 1999 QST 0 Below is the quarterly report for DOE Project DEFC36 99GO10384, titled "Press Dryer Roll Surfaces Web Transfer Systems for Ultra High Paper Machine Speeds ''I. The report is for the period of October 1, 1998 through April 30, 1999.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

May 02, 2017· Tandem rolling is also known as continuous rolling in which two or more set of four high rolling mill arranged in a series in which each set is called stand. These stands are arranged so they can roll the work piece in decreasing cross section. It is used for rolling thick work piece in single pass.

> roll crusher > Qst In Roll Mill Principles; ... Working principle of two roll mixing mill mining ore two and three roll mills procedure Mineral · mining ore two and three roll mills procedure offers 1179 copper ore processing plant products About 55 of these are mineral separator 10 are crusher and 10 are mine mill.

Manufacturer,suppliers exporters of steel rolling mills,steel re rolling mills,steel rolling mill plant manufacturers,steel rolling machine,steel rolling mill for sale,steel rolling mills companies,steel rolling mill process,steel rolling mill project report,steel rolling mill plant manufacturer in India,steel rolling mill machinery,steel rolling mill in India,rolling mill equipment ...

Feeding a roller mill directly from a screw conveyor or bucket elevator will cause surges in the feed rate that the roller mill "sees" instantaneously unless some damping system such as a surge hopper is used. Even though the feed rate averaged out over time may be within acceptable limits, the instant the surge hit the roll the feed rate

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit.

Qst Roll Mill Principles principles of a roll mining mill Products Machinery. principles of a roll mining mill. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. 250tph limestone crushing line in Kenya. 250tph granite crushing line in South Africa.

The invention of the rolling mill in Europe may be attributed to Leonardo da Vinci in his drawings. The earliest rolling mills in crude form but the same basic principles were found in Middle East and South Asia as early as 600 BCE. Earliest rolling mills were slitting mills, which were introduced from what is now Belgium to England in 1590.

We have vertical roller mill principle,Vertical Roller Mill Working Principle There are many different forms of vertical mill but the working principle is basically the same All these forms of vertical roller mill with the grinding roller or the equivalent of grinding roller grinding parts grinding roll along the horizontal circular motion on the disc the vertical pressure exerted on the ...

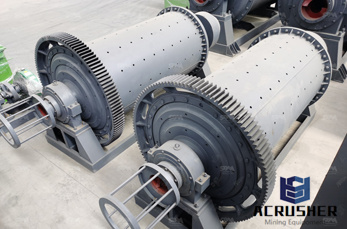

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

WhatsApp)

WhatsApp)