processing steps crusher south africa

rock crusher final step of gold processing Gold Crusher South Africa,Gold Mining . steps in processing gold in south africa . 2013 · gold mining rock ... Barite Mining Processes and Crushing process Steps . .

WhatsApp)

WhatsApp)

rock crusher final step of gold processing Gold Crusher South Africa,Gold Mining . steps in processing gold in south africa . 2013 · gold mining rock ... Barite Mining Processes and Crushing process Steps . .

To make mining efficient and effective, the raw rock and soil are typically not examined onsite. Instead, they are transported to special plants where the ore is processed and the rough diamonds are extracted. Depending on how rich the ore is, a few hundred tons of ore might be sieved just to produce a single carat of gem quality rough diamonds.

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

You''ll need a rock crusher to crush the rock to dust (like wheat flour), something to recover the gold from the dust (panning) and something to melt the resulting gold dust with. There are videos on this. It''s harder than it sounds. Where are you ...

Some children had found a rock and brought it home, and a curious neighbor passed it on to a trader, who gave it to a geologist. It was discovered to be a diamond of enormous size and worth a small fortune. South Africa soon experienced a diamond rush, and .

process of gold from rock to final product in sa; process of gold from rock to final product in sa. Customized products and complete solutions. Heap leaching Wikipedia. The process chosen depends on the properties of the ore. The final product is cathode copper. Nickel ores. This method is an acid heap leaching method like that of the copper ...

Other process used for a long time is the Wohlwill Process and is considered as the second part of the Miller process due to refine its product. This is an electrolytic process based on the dissolution of gold in an acid bath prepared with chlorine gas and hydrochloric acid. The final product is a gold cathode with % purity.

goldsilver sludge was the final product and was further refined in an induction furnace to produce a bullion product off site. The resulting spent electrolyte, containing less than 5 mg/L gold, was recycled to the gold recovery circuit to be used for carbon stripping. A small bleed of

Tumble finishing, also known as tumbling or rumbling, is a technique for smoothing and polishing a rough surface on relatively small parts. In the field of metalworking, a similar process called barreling, or barrel finishing, works upon the same principles.. This process is very similar to the natural processes that produce "sea glass" or "beach glass".

Wide, shallow pans are filled with sand and gravel (often from river beds) that may contain gold. Water is added and the pans are shaken so that the gold is sorted from the rock and other materials. Because gold is much more dense, it settles on the bottom of the pan. Pilgrim''s Rest in Mpumalanga was the first site for gold panning in South Africa.

The final product grade depends on the gold ore treated. This means that high head grades will allow getting a final product with high gold content. As example, in places where there are important contents of silver, the final product can content 75 to 85% of gold.

Aug 18, 2015· The final step in production is smelting. This process involves melting the concentrate in a furnance to extract the metal from its ore. The ore is then poured into moulds, producing bars of bullion, which are then ready for sale. Closure and reclamation. The fifth and final stage in mining operations is closure and reclamation.

Sep 01, 2019· In this video I follow these amazing craftsmen while they go through the entire process right from design to final product. ... videos about gold mining, gold panning, prospecting, rock .

process of gold from rock to final product in sa. Benjamin Fulford Reports AntiMatrix. Bilderbergers announce New World Order of the Illiminati and Single World Empire William C. Van Duyn''s Opening Remarks Bilderberg Mtg. .

Gold will be recovered from the leached solution using carboninpulp process (CIP). Carbonloaded gold will then be screened, washed with dilute hydrochloric acid, and transported to electrowinning cells to recover final gold. The resulting final product will be washed, filtered, and dried before smelting.

Start studying Environmental chapter 16. Learn vocabulary, terms, and more with flashcards, games, and other study tools. Search. ... the price of the final product must be greater than the cost of extraction. Metallic Minerals. ... the process of returning land .

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

The Miller process is rapid and simple, but it produces gold of only about percent purity. The Wohlwill process increases purity to about percent by electrolysis. In this process, a casting of impure gold is lowered into an electrolyte solution of hydrochloric acid and gold chloride.

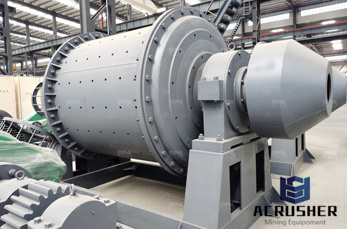

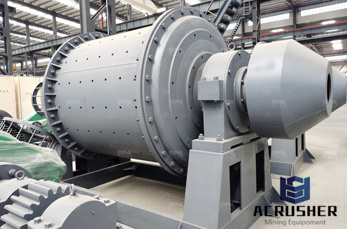

The grinding process reduces the rock to a slurry. The SAG mill is a large revolving cylinder. Rock is ground by the turning action of the mill, and impact from the hardened steel balls and the rock itself. In order to ensure that the rock is ground finely enough the SAG mill has a trommel screen (5), which acts like a large sieve.

process, remove most of the waste rock and concentrate the minerals into approximately 25,850 tonnes of ... gold is still the most important product as the copper and silver is only 1015% of the value of the concentrate. ... copper is first separated from the gold and silver and these are treated separately to get the final metal product.

Getting your kids started on rock polishing helps get them on the road to a lifelong interest in nature and the world around them. Rock polishing is not only a learning experience— it also leads to a beautiful finished product that kids will be proud to show off. Imitation of nature. Rock tumblers are designed to imitate a natural process.

South Africa dominates world production of platinum. Because of the high value of the PGM products, a very riskaverse, conservative approach has been adopted to the introduction of changes in processing technology, and PGM matte smelting remains very closely .

Each process relies on the initial grinding of the gold ore, and more than one process may be used on the same batch of gold ore. Mining 1 In lode or vein deposits, the gold is mixed with another mineral, often quartz, in a vein that has filled a split in the surrounding rocks.

WhatsApp)

WhatsApp)