Aluminum Holding Furnaces NonFerrous Melting Furnace ...

Aluminum Holding Furnaces available in both electric and gasfired designs. Save production time and cost with a Lindberg/MPH Aluminum Holding Furnace. Industry''s single source for .

WhatsApp)

WhatsApp)

Aluminum Holding Furnaces available in both electric and gasfired designs. Save production time and cost with a Lindberg/MPH Aluminum Holding Furnace. Industry''s single source for .

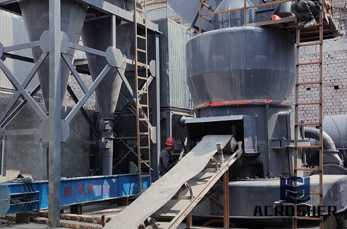

The tilting rotary furnace range combines advanced melting technology, process control and high quality engineering. It is aimed primarily at recycling applications. The advantages and flexibility of the tilting rotary furnace continues to deliver savings and efficiencies throughout the aluminum .

One typical use for rotary furnaces is powders that require frequent exposure to fresh process gas, such as the reduction of a metal oxide with hydrogen. This reaction involves water, and the water vapor is heavier than the hydrogen which means it normally sits at .

May 04, 2019· Casting is a great way to make your own custom metal parts. However, casting requires some manner of furnace capable of generating high enough temperatures to melt the metal in .

We offer technology and s olutions for secondary aluminum casthouses. Melting Solutions'' furnaces and secondary aluminum processing equipment have the most technologically advanced methods for melting all types of scrap and recycling into foundry ingots. These are then ready to .

Jul 05, 2016· Another essential structure is an oven for MELTING metallic objects and creating new ones. Click HERE to subscribe to Make it Extreme:

The molten aluminum is then pumped into a holding furnace. Holding furnaces are better suited for final alloying, and for making any additional adjustments necessary to ensure that the aluminum meets product specifications. Pouring takes place from holding furnaces, either into molds or as feedstock for continuous casters.

Rotary furnaces are used in mass production to heat smallmetal billets before forging. The rotary furnace is similar indesign to the ring furnace and differs only in the shape of therotating sole and the working space. Articles are loaded and discharged through a single window, usually by hand. The outerdiameter of the rotary furnace is up to 5 m.

This furnace is used for melting aluminium scrap of all types (dirty scrap, borings, etc.) so the refractory solution depends a lot on the salt level of the liquid metal. Another important factor when deciding on your refractory lining is abrasion resistance of both the charge itself and of the cleaning tools.

DIY Metal Melting Furnace: In this indestructible I will show you how to make a metal melting furnace that can heat up to 1,500 degrees Frenheit.

Oct 01, 2019· How to Build a Metal Melting Furnace for Casting. If you want to cast metal into different shapes, you need to have a furnace that gets hot enough to melt the metal. While you can buy premade furnaces, you can also make your own using an...

The basic components of a rotary kiln are the shell, the refractory lining, support tyres (riding rings) and rollers, drive gear and internal heat exchangers. History. The rotary kiln was invented in 1873 by Frederick Ransome. Kiln shell

PDF | This work provides an overview of the aluminum (Al) recycling process, from the scrap upgrading to the melting process. Innovations and new trends regarding the Al recycling technologies are ...

Sep 17, 2001· 3. Rotary piercer. 4. Floating mandrel mill. 5. Reheat furnace. 6. Stretch mill. 7. Cuttolength equipment. Step 1: Rotary Furnace. This inline process starts off with an ascast round billet produced from ladlerefined steel originating from either a basic oxygen furnace (BOF) or electric arc furnace (EAF) melting process.

Variety of nonferrous melting and holding furnaces available for a range of applications. Maximize production rates and save costs.

The furnace we built is a small helium tank furnace, capable of melting 30 lbs of bronze in about 40 minutes. This is exactly the same furnace I use in my own studio. The features of this furnace are: Melts 30 lbs of bronze in 3040 minutes; Uses a party helium tank (the same size as a 5 gal propane tank) Inexpensive to make: under 150

Dr. Dmitri Kopeliovich Fluxes for melting aluminum are solid substances (commonly mixtures of chloride and fluoride salts) used in aluminum foundries in order to reduce the melt oxidation, minimize penetration of the atmospheric Hydrogen, absorb nonmetallic inclusions suspended in the melt, keep the furnace/ladle wall clean from the built up oxides, decrease the content of aluminum entrapped ...

Aluminum Melt Furnaces: Principles of Fuel Economy by Al Kennedy, Kennedy Eurotech, Inc. Abstract The goal of this paper is to review basic principles that affect the energy efficiency of gas and oilfired furnaces for melting and holding aluminum. Because there are so many different types

During secondary aluminum recovery, complex aluminum scraps are melted and refined often in a rotary melting furnace, and the aluminum metal has to .

Metallurgical Furnaces 1 MetallurgicalFurnaces For other industrial reactors and their applications, see →StirredTanc and Loop Reactors, →Tubular ... 2 Metallurgical Furnaces A rotary kiln is an inclined, rotating cylindri ... the metal is volatilized under reducing conditions. The vaporized metal is oxidized in the

This step deals with Furnace Casting and Coil Bending of the aluminum furnace. Furnace Casting 1. Take 1/4 of the cement powder you have (250g min) and mix it well with water 2. Pour it into the steel pot and let it set and harden into a level concrete surface 3. Make a cylinder that snugly fits around the milo tin using the sheet of cardboard and some tape 4.

Every Harper rotary tube furnace is designed for the customer''s unique specifications. We bring innovative solutions to designs for continuous processing of advanced materials such as granular, powder, or particulate aggregates in high purity and specialty atmosphere environments at temperatures up to 3000°C, including gas, electric and microwave heated systems.

Tilting rotary furnaces are used for recycling of aluminium scrap, which give higher recovery compared to reverberatory furnaces (Skelner Furnace). Recycling rates. Brazil recycles % of its aluminium can production, equivalent to billion beverage cans per year, ranking first in the world, more than Japan''s % recovery rate. Brazil ...

offers 17,480 aluminium melting furnace products. About 82% of these are industrial furnace, 1% are metal casting machinery, and 1% are jewelry tools equipment. A wide variety of aluminium melting furnace options are available to you, such as melting furnace, muffle furnace, and heat treatment furnace.

WhatsApp)

WhatsApp)