Gypsum Board Manufacturing Plant Project Report: Industry ...

IMARC''s latest study "Gypsum Board Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue" provides a .

WhatsApp)

WhatsApp)

IMARC''s latest study "Gypsum Board Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue" provides a .

Globe supplies a full range of material handling and process equipment for the gypsum industry. Globe Machine | Gypsum Board Manufacturing Equipment A Manufacturer of Industrial Machines, Systems, and Plants for Advanced Composites, Building Products, and Pulp Paper

In Gypsum Product Manufacturing, the chemical composition of gypsum is calcium sulfate dihydrate (CaSO4·2H2O). There are two types: natural gypsum and FlueGas Desulfurization (FGD) gypsum. FGD gypsum is a byproduct of desulfurization of flue gas from the stacks of fossilfueled power plants.

To produce gypsum board, crushed natural gypsum or synthetic gypsum is is heated or calcined to dehydrate the feedstock. Next the calcined gypsum is mixed with water and additives to form a slurry which is fed between continuous layers of recycled paper on a long board machine.

MANUFACTURING SUSTAINABILITY PROCESS. ... our design teams use lifecycle thinking to improve the sustainability of a product. ... CertainTeed gypsum participates in the UL environment ECV program for multiattribute sustainability claims for all manufacturing plants and gypsum board products.

Raw material: Gypsum Manufacturing Process and Source of Technology Gypsum is the basic raw material required to manufacture Plaster of Paris. These are cleaned and washed for removal of impurities, dried in sunlight and then pulverized. Gypsum powders are calcined in a rotary drum calcinatory using light

During the process, semidry gypsum injected into the cavity in a low waterpowder ratio powder status. Natural Gypsum Powder Plant We offer a complete natural gypsum plant solution according to the location of your factory, plant area and market conditions. Production power of our plant is 20,000/ Year .

It looks like you entered an employee email address, but this is the customer signin. Use the link below instead. Employee Signin

GRP MANUFACTURING PLANT . ... GYPSUM COMPOSITES INTERNATIONAL manufactures glassfiber reinforced plastic pipes by a filament winding process for application in various water and wastewater network systems. Our core competency is in manufacturing of egg and special shaped profiles – the GCI GRP Structural Liner – with a length of up to 6 ...

gypsum board manufacturing plant Alibaba. gypsum board manufacturing machine,dry mortar mixing plant 40t/h gypsum board production equipment in dubai is widely used for mixing of powder, granular, flake block, irregular and sticky materia l s in the industries of feed, cereal, food, chemicals, medicine, pesticide, etc. is the professional manufacture of Drymortar equipment with design ...

The production of wet process phosphoric acid generates a considerable quantity of acidic ... U. S. generally use a dihydrate process that produces gypsum in the form of calcium sulfate with 2 molecules of water ... Final disposition of the volatilized fluorine depends on the design and operation of the plant.

Drywall (also known as plasterboard, wallboard, sheet rock, gypsum board, buster board, custard board, or gypsum panel) is a panel made of calcium sulfate dihydrate, with or without additives, typically extruded between thick sheets of facer and backer paper, .

Gypsum waste from the manufacturing of gypsum products. This waste, which arises at the industrial gypsum production sites, consists of rejects and nonspec materials generated during the manufacturing of gypsum products. The recycling of this waste stream is usually part of the waste avoidance activity of the gypsum plants.

Configuration of Bhutanese gypsum plant and production of gypsum plaster by the process suggested by CBRI visàvis to process adopted by the plant have been explained. Gypsum at 180°C with 1 h .... followed at the plant). Plaster design. Read More

A gypsum block is made of gypsum plaster and water. The manufacturing process is automated at production plants where raw gypsum (CaSO 4 ·2H 2 O) is ground and dried, then heated to remove threequarters of the bound water and thus transformed into calcium sulfate hemihydrate (CaSO 4 ·½H 2 O), also known as gypsum plaster, stucco, calcined ...

evaluation of potential commercial processes for the production of ... basic chemical and physical properties of the natural gypsum used to manufacture ..... The design and operation of this type of plant seems feasible as a method of .... Several articles and a patent involving the production of .

In the hope of each production stage becoming a vessel for realizing a recycleoriented society. At Chiyoda Ute, more than 50% of our current production activity takes place with recycled material. We aim for zero plant emissions through recycling, using byproduct gypsum for the core, recycled paper for the paper facing,

Natural gypsum: CaSO 4. 2H 2 O Taking the example of synthetic gypsum manufacturing by power plant As the power plant has the excess SO2 produced at the plant, these gases are called as Flue gases which are exposed to slurry of hydrated lime. This lead s to the formation of calcium sulphite (CaSO 3. ½ H 2 O)

chemical gypsum powder production line keuken310nl Gypsum Powder Processing Plant,Gypsum Powder Production Line Gypsum Powder Processing Plant,Gypsum Powder Production Line As a member of the five gel materials, the gypsum powder plays a key role in the national economy and has been widely used in the fields of construction material ...

Detailed Project Reports Profiles on Gypsum Plaster Board Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue

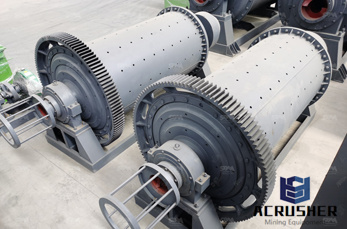

Cement Production: Cement. Aggregates. Admixtures. ... higher and the output lower than in the dry process. However, blending is much easier in a wet state. Most modern plants opt for the dry process with preheaters and precalciners. ... in a ball mill, the particles are crushed by the impact of steel balls. Gypsum is an essential additive, as ...

Presented at Global Gypsum Conference 2016 by Robert Morrow. Building a gypsum board factory can be complicated! There are many decisions to make regarding the location of the plant, the conditions and expectations in the local market, the size, layout and scalability of the plant, the technology of the equipment (calciner, mixing, dryer), the options for equipment suppliers, the intended ...

gypsum rock are mined each yearover 240,000 tons of it destined for Portsmouth. At their wallboard plant in Portsmouth, television crews filmed the rock''s movement through every step of the manufacturing process. "The employees at Halifax and Portsmouth did an exceptional job in preparing for the show," Peter Browning said. "They ...

A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure In this process gypsum is crushed, dried, ground, and calcined. Not all of the operations shown in Figure are performed at all gypsum plants. Some plants produce only wallboard, and many plants do not produce soil ...

WhatsApp)

WhatsApp)