(PDF) Control for pulverized fuel coal mill

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat ...

WhatsApp)

WhatsApp)

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat ...

10th IFAC International Symposium on Dynamics and Control of Process Systems The International Federation of Automatic Control December 1820, 2013. Mumbai, India Modeling and Control of Coal Mill P Pradeebha, N Pappa, D Vasanthi Department of Instrumentation Engineering, Madras Institute of Technology, Anna University, India.

Nonlinear coal mill modeling and its application to model predictive control. ... This limit is imposed by the size of the coal mill and by the available grinding capacity of the rollers. The parameter BR 1 can be used to simulate a deterioration of the roller performance ( due to .

A unified thermomechanical model for coal mill operation ... Dynamic coal mill model based on conservation laws and empirical relations. •. A model which can replicate the entire milling operation from startup to shutdown...

offers 4,651 coal grinding mill products. About 68% of these are mine mill, 4% are grinding equipment, and 1% are flour mill. A wide variety of coal grinding mill options are available to you, such as raymond mill, ball mill, and end mill.

Aug 13, 2019· HBM series vertical energy saving vertical grinding mill machine researched and developed by our company engineer who have been spending his whole life basing on the national mill "E"model ...

CFD Modeling of MPS Coal Mill for Improved Performance and Safety . ... The MPS mill at Alliant Energy''s Edgewater Unit 5 ... A newly developed coal mill model provides a valuable tool that can ...

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

Sourcing Guide for Coal Mill: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: grinding machine, milling machine, grinding mill.

A study of ultrafine grinding of lowrank coals in a fluidenergy mill was undertaken. The overall project objectives were to (1) measure selected properties of ultrafinepulverized, lowrank coal as a function of coal source and product moisture, and (2) determine the power requirements for a fluidenergy mill to produce /minus/10 micron sized particles as a function of coal source and ...

This paper presents a coal mill model that considers the effect of coal moisture on its accuracy. This mathematical model is derived through the analysis of mass flow, heat exchange, and energy transferring balances in which all heat input into or output from the coal mill are calculated quantitatively to reduce the number of unknown parameters that need to be identified.

Product Name Coal Grinding Mill manufacturer Model YGM7826 model Color White, Yellow, Blue, Red Standard CE ISO Capacity 25500kg/h based on different hardness materials Motor power for main unit, 15KW for blower, for the classifier Fineness can be adjustable Used building industry machinery, mining, chemical and so on Products Show Spare parts Our .

offers 13,449 coal mill machine products. About 31% of these are mine mill, 2% are grinding equipment, and 1% are flour mill. A wide variety of coal mill machine options are available to you, such as raymond mill, ball mill.

Modeling on the Effect of Coal Loads on Kinetic Energy of Balls for ... Jul 9, 2015 ... kinetic energy, the friction energy consumption, and the mill''''s total work. Meanwhile, ... Their coal grinding efficiency is closely related to the economy of the power plant, as ..... Correlation Degree and Balance Degree Method. Read More

2017 Lianke machinery 3r coal grind mill 3R500 model 3 roller vertical raymond ... rock phosphate, coal and other materials, total about 400 kinds of materials. Products Show Working Principle of Ball Grinding Mill The energysaving ball mill is a horizontal cylindrical rotating device, outer gear, the two positions, lattice energysaving ball ...

Patent CNY Fire coal power plant boiler cold ... The utility model provides a fire coal power plant boiler cold state pulverizing apparatus, comprising a coal mill, an .

New results from a systematic grinding study with the larger, SM 320 Szego Mill are reported. A wide range of flow rates, from 750 to 5300 kg/h of coal, at 6065% solids concentration has been covered, with both single and multiple passes through the mill. Particle size distributions and power ...

article{osti_, title = {Techniques and relative energy requirements for finecoal grinding}, author = {Notestein, }, abstractNote = {The Coal Grinding Task Group basically characterized coal grinding technology (June 1982) with an emphasis on identifying any needs related to producing very fine coal (<325 mesh). The underlying assumption was that future coal usage in nondesigned ...

2 Figure 2 Tube Ball Mill Structure II. MATHEMATICAL MODEL OF TUBEBALL MILL The procedure for coal mill modelling can be broken down into the following steps: 1) ΔTo derive the basic mill model dynamic equations through analyzing the milling process, applying physics and

A unified thermomechanical model for coal mill operation. ... Some attempts have also been made to estimate moisture content of coal in the mills using simplified energy balance model (Andersen, Bendtsen, Pedersen, ... The physical processes associated with mills such as grinding, coal entrainment, drying, heat transfer, and classification are ...

Pulverizer Wikipedia coal mill model uml diagrams,A pulverizer or grinder is a mechanical device for the grinding of many different types of example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plantsp amp i diagram for cement mill amp i diagram for cement mill coal mill model uml diagrams ...

Download Citation on ResearchGate | Modeling of a medium speed coal mill | This paper presents a coal mill model that considers the effect of coal moisture on its accuracy. This mathematical model ...

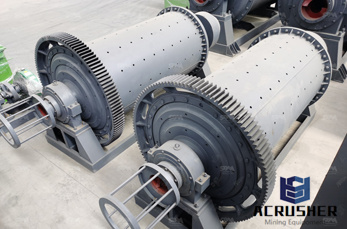

The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed. Blending of explosives is an example of an application for rubber balls.

Pulverizer . A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in .

WhatsApp)

WhatsApp)