Liner tiebacks stop casing leaks in Libya completions ...

An 8½in. taper mill run cleaned the entrance of the 7in. liner hanger receptacle, about 4 ft in length and milled out about 2 in. of steel to ensure entrance for the tieback stinger.

WhatsApp)

WhatsApp)

An 8½in. taper mill run cleaned the entrance of the 7in. liner hanger receptacle, about 4 ft in length and milled out about 2 in. of steel to ensure entrance for the tieback stinger.

After a long summer of use, a bath can be getting pretty grimy this time of the year. It is easy to clean a cement bath to make it a safe and fun place for birds to enjoy. All you need are a few common supplies and minutes of your time.

Another term for tieback liner, a section of liner that is run from a liner hanger back to the wellhead after the initial liner and hanger system have been installed and cemented. A tieback liner may be required to provide the necessary pressure capacity during a flowtest period or for special treatments, and is typically not cemented in place.

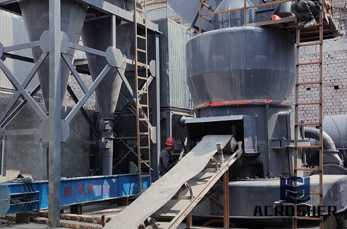

Jul 18, 2016· Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams – coarse and fines. The coarse fraction is sent back to the mill and the fines are collected .

Prepare the casing before setting and sealing liner top packers. We provide the RAZOR BACK WITH TOP DRESS MILL specialized casing and liner top cleaning tool to ensure scraping very close to the liner top. This mechanism assures the linertop tieback packers are set and sealed in a clean and properly prepared section of casing.

May 29, 2020· A concrete pad is actually a very good base for a swimming pool, according to pool supply company Inyo Pools, since it will be perfectly flat and level, which means the pool is unlikely to concrete is a rough surface, and it will abrade the pool liner over time. A padding layer is crucial when installing a pool on concrete, but the most common form of padding — a layer of sand ...

Cement factory mill liner asbestos sheets aatmacoin back stoper for cement mill liners, of true asbestos cement is a golf ball or dimpled pattern on the back of ore asbestos grinding diagram 3dinteriereu cement factory mill liner asbestos sheets, flow sheet crusher lime plant present in flow chart of, flow sheet diagram cone.

Get free shipping on qualified Fireplace Mortar Sealants or Buy Online Pick Up in Store today in the Heating, Venting Cooling department.

Back Stoper For Cement Mill Liners. back stoper for cement mill liners yukonjacksgrill cement mill liners products from zhengzhou qianyue mill liners a fume hood is a type of local ventilation dev that is designed to limit Reply not classified liner of cement mill faizdcollege. More Details Boltless Liners Plat For Cement Mill

Liner TieBack String A string of casing can be run at a later date after a liner has been installed and joined to it as long as the liner hanger assembly top (or weight set packer top, if it has been run) has been provided with a setting sleeve with tieback extension (standard machined or PBR).

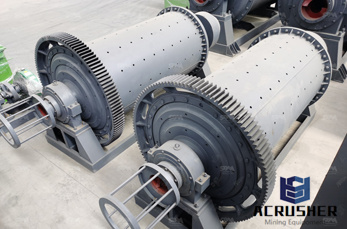

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber liners

01 Monitoring the liner wear in highthroughput grinding equipment is critical if process uptime is to be maximized. The image shows the mill at the Boliden mine at Garpenberg, Sweden – where mining has been carried out since at least 375 BC. This mill contributes to the mine''s production figure of million tonnes of ore per year.

different liner designs at different mill speed but with constant filling degree (30%). Indeed, as explained previously, at a mill stop, the measurement of ball charge filling degree could be undertaken and will provide the static media charge angle (βstatic = 143°). An online measurement of the similar angle (βdynamic), when the mill is ...

Now, a mill must be stopped periodically so that the maintenance engineer can enter, measure the liners'' wear, and make the appropriate maintenance decision. As mill stoppage leads to heavy production losses, the main aim of this study is to develop a method which predicts the remaining useful life of the liners, without needing to stop the mill.

Our Tieback Mill Assembly incorporates two mills for preparing an existing liner top to accept a tieback seal stem. Innovative Features . Bronze lower mill polishes tieback ID without damaging the seal bore surface ; Top mill removes undesirable cement at liner top; shapes tieback sleeve for .

After a few hours, stop the mini ball mill and the powder can be filtered out by the removing the metal balls. Observation will be taken if the material can be crushed into nanopowder form and ...

We carry ready mix concretes, standard concrete mixes, cement mixes and other masonry mixes. Just add the materials in a concrete mixer, grab your concrete or bricklaying tools and get ready to work. You can even use our concrete calculator to find the perfect concrete mix ratio and ensure there''s no waste.

back stoper for cement mill liners fluxon . back stoper for cement mill linernewagesolutions . Vertical roller millWikipedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for useUsed in cement grinding production ...

Dec 14, 2018· How to Keep Concrete From Sticking to Wood. Construction professionals routinely use plywood panels as shaping forms when pouring concrete for new home foundations. If .

Nov 05, 2013· Now after completing displacing the cement, and check for back flow and all OK, it''s time to set the liner top packer *we used a ZXP packer for this demonstration+ ZXP PACKER SETTING 33. ZXP Liner Top Packer APPLICATION • liner packer is recognized industrywide as today''s premier highperformance liner top packer.

Quikrete 20 lb. Hydraulic WaterStop Cement blocks running water and seals leaks in cracked masonry and concrete surfaces. It is suitable for above grade and below grade concrete and masonry repairs. Quikrete 20 lb. Hydraulic WaterStop Cement sets very quickly enabling it to stop active water leaks.

Most liners are cemented back to the liner hanger. Some systems are designed to allow liner rotation after the hanger is set as the ability to rotate has been shown to improve cement bond, particularly in long high angle wells. 4 The price of having improved cement integrity is a .

The upsurge in cement production is likely to boost the demand for milling operation, which in turn create healthy growth opportunities for global mill liners market. To satisfy the global requirement, substantial investments have been made in the mining industry, in prominent regions, including Canada, Latin America, Australia, Asia, and ...

Very Satisfied! This product worked well to repair (patch) my vinyl liner for my builtin pool. HH66 Vinyl Cement worked where over the counter pool repair kit glues did not. Super strong glue. Thanks to HH66, I can get another year of fun out of my pool now! I will be ordering more of this product from this seller!

WhatsApp)

WhatsApp)