Aluminium cold rolling mill YouTube

Feb 22, 2017· For further information, please contact Jane. Whatsapp:+ Email: hnhzzg

WhatsApp)

WhatsApp)

Feb 22, 2017· For further information, please contact Jane. Whatsapp:+ Email: hnhzzg

ALUMINUM COLD ROLLING MILL — A SINGLE HIGHPRECISION MILL FOR BOTH BREAKDOWN AND FINISHING Primetals Technologies'' aluminum cold rolling mills offer a blend of innovative design and proven technology for both new and revamp projects.

Aluminum Cold rolling mill is used to altered the aluminum coil of thickness 10mm down to down at temperatures below the aluminum''s recrystallization point. Cold rolling mill is comprises of main stand, hydraulic press, work rolls, gear units, lubrication system, pneumatic system and other necessary equipment.

Aluminum alloy: 1000,3000,8000 series Entry thickness: Max mm Dia. of working roll: Φ200~320 Width of work roller: 800~2300 mm Dia. of back up roll: Φ550~850 mm Width of backup roller: 750~2250 Weight of coil: 30000 max kg Rolling speed: 2000 max m/min Foil roughrolling thickness: ~ mm Thickness of foil rolling: ~ mm Exit of AL foil .

From hot to cold covering a wide variety of needs . Union Electric Åkers supplies rolls to some of the world''s leading aluminum mills. We were the first roll manufacturer to introduce the 5% Cr and 10% Cr semi HSS grade with considerably improved performance for the hot mill process.

Jun 21, 2017· According to the development of the aluminum foil, the aluminum foil manufacturing process mainly has the following three methods: Lap rolling method, strip rolling method and deposition. 1. Lap rolling method Lap rolling method is adopt multilaye...

Customized aluminum foil rolling mill. The aluminum foil rolling mill can process max material into foil material with all kinds of gauge and width. These processed foil can be offered as further processing raw material . Continue Reading

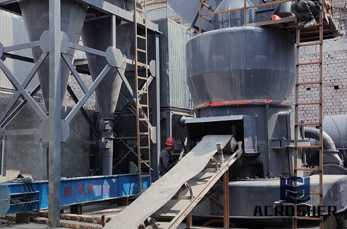

Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. is an aluminum equipment company, our main products include aluminum cast rolling mill, cold rolling mill, aluminum foil rolling machine, tension leveling line, cut to length line, slitting line, cast roll, roller sleeve, steel sleeve, etc.

Logan Aluminum Rolling Mill To meet the beverage industry''s growing demand for light gauge, tighttolerance aluminum sheet stock, Logan Aluminum committed to a major capital expansion project. A critical requirement during the project execution was the continual operation of the existing mill without production disruption.

the hot rolling mill is coiled for transport to the cold mill which might be on the same site or elsewhere. Cold mills, in a wide range of types and sizes are available; some are single stand, others 3 stand and some 5 stand (Figures and ). Cold rolling speeds vary but modern mills operate at exit speeds as high as 3000 m per

Nowadays, Eualu has occupies around 300,000㎡, which includes a hot rolling reversing mill with single housing and double curling, whose diameter is 1850mm, 2 cold rolling mills with 1850mm diameter, 2 cold mills processes with 1450mm diameter, 1 foil rolling mill with 1450mm diameter, and 4 color coating processes, 2 of which are full for ...

Petral ADE Additive for finishing mills Cipar V 80 Edge Cutting Oil Petral ADD Additive for finishing mills Petrocut AL 5000 Slab/billet cutting oil ROLLING OILS/ADDITIVES AND ANCILLARY LUBRICANTS PETRAL© SERIES Rolling Oils For Aluminum Sheet and Foil Production. HYDROIL SERIES Rolling Oil Compatible Stain Free Fluids. CIPAR V80 Edge .

Apr 07, 2016· Cold rolling mill and annealing furnace ... Our main products include aluminum cast rolling mill, cold rolling mill, aluminum foil rolling machine, tension leveling line, cut to length line ...

A wide variety of new and used aluminum rolling mills and equipment including aluminum foil rolling mill, cold rolling mill, continuous casting mill and hot rolling mill are available with complete technical services from our own specialized engineering team.

If you search the Internet for what a coldrolling mill is, one might be hardpressed to find a description to relate to and understand. It is important to preface that what is involved in the process of rerolling aluminum coil or strip is quite capital intensive, which explains why there are limited mills in the United States that will flat roll aluminum coil.

Aluminium Rolling Lubrication: part 2. It is now accepted that aluminium rolling lubrication strongly influences both mill productivity and metal quality. Following on from our last blog post, we will now introduce you to aluminium rolling lubrication for Cold Foil Rolling and WaterBased Cold Rolling. Cold Foil Rolling

Haomei Aluminum has total annual production capacity of 200,000 metric ton aluminum foil, strip and sheet. It is equipped with 1+4 hot tandem rolling line, 4 cold mill production lines, and 5 foil mill production lines, and a complete complex of fishing equipment.

ABOUT AMAG. AMAG Austria Metall AG is a supplier of primary aluminum and premium cast and rolled aluminum products. At our integrated site in Ranshofen, Austria we fully leverage our core competencies in recycling, casting, rolling, heattreatment, and surface finishing.

The use of any information contained herein by any member or nonmember of The Aluminum Association is entirely voluntary. The Aluminum Association has used its best efforts in compiling the information contained in this book. While the Association believes that its compilation procedures are reliable, it does not warrant,

From plate to sheet and aluminum foil. The production of sheet or foil usually starts out the same way as plate but the slab is further rolled through a continuous mill to reduce thickness and wound into a coil at the end of the line. These coils are subsequently cold rolled, from one to several passes at cold rolling mills.

Mold Crystallizer aluminum for continuo; Hengzhong Catalogue; Aluminum Casting roller; Roller shell for cast rolling mill; Aluminum Cold rolling mill; Roll sleeve for aluminum coil; Aluminum foil rolling mill; Aluminum casting mill; Tension leveler line; Cut to length line; Color Aluminum Reflective sheet; Work roll of cold rolling mill ...

Sep 05, 2017· The difference between cold rolled aluminum coil and hot rolled aluminum coil is mainly due to the difference in the production process. Cold rolled is processed by casting machine into casting roll and cold rolling mill. Hot rolling is caused by ...

High Speed Aluminum Cold Rolling Mill The aluminum cold rolling mil can roll the cast coils or hot rolled oils of width mm and thickness 68mm down to .

ALUMINUM FOIL MILL — EFFICIENT PRODUCTION OF HIGHQUALITY, LOWCOST FOIL Primetals Technologies designs the most advanced foil rolling mills in the world, combining the latest developments in automated foil feed, measurement and control to enable producers to achieve the best quality foil at the lowest cost.

WhatsApp)

WhatsApp)